Calidad

Enemies of photovoltaics - Delamination

In this installment we will go deeper into a serious defect that can be found in photovoltaic modules due to poor quality materials and/or handling: delamination.

What is delamination?

We call the phenomenon of the different layers that make up a photovoltaic module losing adhesion “delamination”.

This defect can appear at a very early stage, even just after module installation, and get worse throughout the module's lifetime.

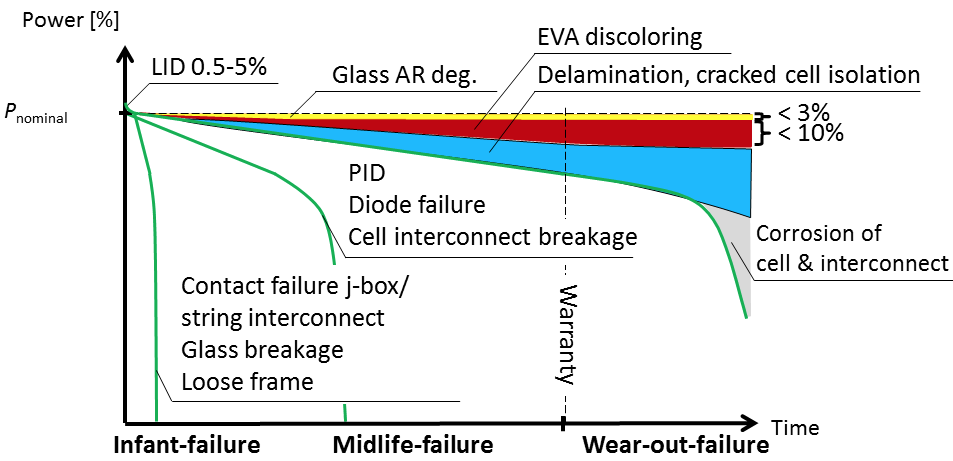

In this image, we can see the impact of delamination on the performance of a module over its lifetime (blue area).

How to avoid delamination?

Module delamination is a defect that can occur at any time during the life of the module, caused by improper manufacturing and/or the use of poor materials. On the other hand, if transport and handling during installation are inadequate, the likelihood of delamination increases over the lifetime of the installation.

The following is recommended to prevent this:

- Buy material from well-known and proven brands, with certified and transparent manufacturing processes.

- Ensure transport to the site with maximum precautions. Modules are delicate equipment and must be palletized with no weight on top, to mention two basic transport conditions.

- Handle the module with care during installation of the material; in addition to following the manufacturer's installation instructions.

- Regularly check the plant. In addition to constant monitoring of the plant, a visual inspection with special measuring equipment should be carried out at least once a year.

With all the measures applied, delamination and many more defects can be effectively combated. All risk prevention work is worth the effort. The cost of repairing defects grows exponentially the later they are discovered, so every penny invested in quality materials, installation and revisions assures an economic benefit.

Why does it occur?

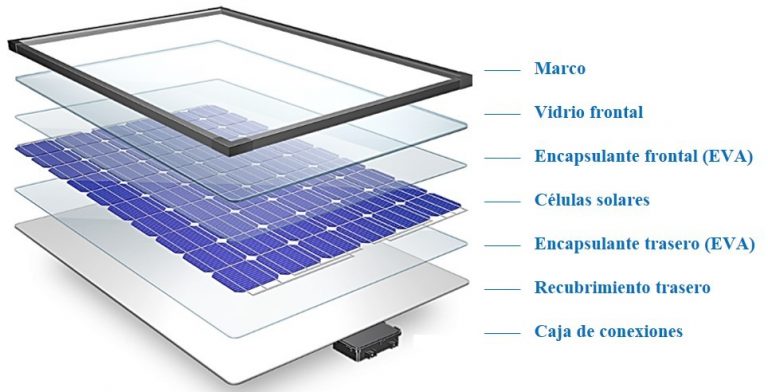

A module is made up of several layers. These are vacuum bonded together during the manufacturing process in an attempt to eliminate any air and moisture that may remain between them. The different layers may lose their adhesion capacity due to inadequate manufacturing and/or the use of poor quality materials. Thus, it will be very important to ensure the quality of the EVA and backsheet, among others.

Here we can see the different layers found in a module.

How is delamination detected?

We can detect delamination with a visual inspection of the module. Color changes of the module, milky spots on the front of the module and/or the formation of bubbles on the back of the module are observed.

What is the origin of delamination?

It may have its origin in the manufacturing of the module, when the layers are not properly laminated. This can happen when the layers do not remain long enough in the so-called "laminator", the equipment used to bond glass, EVA, cells and backsheet.

Another cause is the use of poor quality materials. In particular, EVA and backsheet are prone to lose their adhesion capacity. If we also take into account the permanent exposure to climatic factors such as temperature, humidity and UV irradiation, low-quality modules may start to delaminate shortly after installation. Of course, poor transport and improper handling of the module during installation also lead to the occurrence of the phenomenon.

How does delamination affect the module?

When delaminations are located far from the edge of the module, they negatively affect performance, although they do not necessarily constitute a safety problem. However, these delaminations may extend to the edge of the module. Thus, they may can come into contact with the environment allowing air and moisture to enter, causing corrosion and irreversible destruction of the module, affecting the integrity of the plant